Hazira Flow Meter Calibration Facility

Hazira Meter Prover Facility (HMPF) is one of the world’s leading high-pressure test facilities for gas meters. The facility have widest range of flow meters calibration capacity for the Mass Flow Meters, Ultrasonic flow meters, Turbine meters and other volumetric flow meter. It is installed and operational at Hazira Compressor Station, Surat (Gujarat).

Hazira Meter Prover History

GAIL India Limited was incorporated in August 1984 as a Central Public Sector Undertaking (PSU) under the Ministry of Petroleum and Natural Gas (MoP&NG). The company was initially given the responsibility of construction, operation & maintenance of the Hazira - Vijaypur -Jagdishpur (HVJ) pipeline Project. The pipeline was commissioned by the end of July 1987. Since its commissioning, the need for gas meter calibration has been catered by the Hazira Meter Prover Facility.

Journey So Far

Year - 1987

The calibration facility was first commissioned in 1987 along with the HVJ pipeline project. It was initially designed to cater only up to 12 inches size and 600 class turbine flow meters.

Year - 2012

As technology improved and different kinds of gas flow meters came into use, Hazira Meter Prover facility underwent major upgradation in 2012 and was fully equipped to calibrate all types of volumetric gas meters ranging in size from 2 inches to 20 inches.

Year – 2016

Accreditation of HMPF for volumetric flow by NABL in accordance with ISO/IEC 17025

Year - 2020

As the demand to carry out calibration of large size meters arises, the facility expanded to cater the calibration of meters upto 30inch size.

Year - 2022

Facility enhanced its NABL scope to cater the calibration of Mass Flow Meters.

Specification

| Type of facility | Open loop |

| Flow Range : | 10 to 19,000 m3/h |

| Meter Sizes: | 2 to 30 Inches (DN 50-750) |

| Pressure: | 46 to 51 bar (As per line condition) |

| Medium: | Natural Gas |

| Best Overall Uncertainty (CMC): | 0.16% |

| Temperature Stability: | better than 0.05 Deg C per test run |

| Pressure Stability: | better than 0.05 bar per test run |

| Parallel Calibrations: | 4 Measurement Sections (including series calibration) |

| Number of Master Meters: | 7 x 2 |

| ANSI Flange Rating: | ANSI 300# and above |

| Test length | 18.5 Meter |

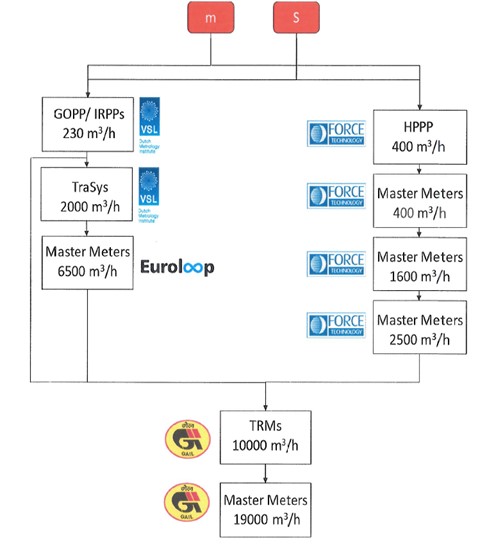

Traceability Chain

Hazira Meter Prover is traceable to International SI units ‘Meter’ and ‘Second’ through primary flow elements – Gas Oil Piston Prover (GOPP) of M/s VSL, Netherland / High Pressure Piston Prover (HPPP) of M/s Force Technology, Denmark.

Hazira Meter Prover Facility is initially certified and traceable to GOPP of VSL in 2013 through NMI Euroloop. With Effective from 2020 it is traceable to primary standard at Force technology. HMPF owns its own Travelling Reference Meters (TRMs) which are calibrated directly or indirectly with primary flow elements at VSL / Force, which have been in turn used to calibrate the Hazira Meter Prover Facility.

CALIBRATION PRINCIPLE

Gas Calibration Principle

Hazira Meter Prover Facility uses the Master Meter method based on the mass conservation principle. In this a master meter and test meters are kept in series and mass entering and exiting the loop remains fixed. The volume quantities of the meters are converted to mass using the actual density and real gas factors calculated using an online gas chromatograph in the system. All quantities measured are corrected for deviations. In addition to these corrections the double timing method is used to avoid truncation of pulses in the time interval during which a calibration run is performed.

Calibration Request Form

When the request for calibration is received from a customer, a Calibration Request Form is sent to the customer to indicate all information related to meter necessary for the calibration. Based on this information, slot of the calibration is booked and is intimated to the customer.

Receipt of Meter

Based on calibration slot, customer is asked to dispatch the meter at least a week in advance. Meter received is inspected for any physical damage and an acknowledgement of the receipt is sent. After preliminary servicing of the meter including cleaning, lubrication, spin testing, electronics check etc. the meter is labelled and put in storage, waiting for calibration.

Meter Setup for Calibration

Meter under Test line is depressurized and meter is installed at designated place. Though the facility has a large inventory of spools and reducers in different schedule size which can be used on customer suitability, still we suggest bringing the actual inlet and outlet spools that will be used in field with the meter to be tested. The line is then pressurized and thorough leak check is performed.

Calibration Process

A typical calibration starts with running the meters under test at maximum flow rate for stabilization of the process parameters. During this stage, temperature and pressure differences in the pipe system are equalized. Then the meter is calibrated starting with Qmax and followed by the lower flow rates. At each flow rate a minimum of three runs are taken, each of minimum 60 seconds. The results are listed on the calibration certificate.

On request the calibration results will be compared with performance criteria as stated in the European Measuring Instruments Directive (MID), OIML R137-1, 2, AGA-7, AGA-9, ISO 9951, ISO 17089-1, EN 12261 or customer specifications. If necessary the meter will be adjusted and one or more verification runs will be performed to verify the correctness of the adjustment.

After Calibration

After calibration the test line is disassembled and the meter is prepared for shipping. Electronic certificates and other required data is sent by e-mail while original certificates are sent by courier service.

Witness

For each calibration, the customer or its representative is invited for witnessing the process.

Safety

GAIL has a very well documented & established Health, Safety & Environment (HSE) policy. Adhering to this policy, strict safety rules are also followed at the Hazira Meter Prover Facility. The facility confirms to the globally accepted ATEX safety standards. All personnel and visitors are required to wear personal protective equipment while they are inside the facility. At Hazira Meter Prover facility we ensure safety of all our stakeholders.

CONTACT

Hazira Meter Prover facility is available all year round, independent of the season. Please contact us for time slot or any general query and requests.

GAIL (India) Limited,

Hazira Flow Meter Calibration Facility

Hazira Compressor Station

Ichchapore Magdalla Road,

P.O. ONGC Nagar, Surat – 394510,

Gujarat, India

T: +91 261 2290300/ +91 8980399966

E: prover[at]gail[dot]co[dot]in

Contact Person:

Kishor Patel, DGM (NG P/L O&M), Extn: 460 (Email: kishorepatel[at]gail[dot]co[dot]in)

Akash Kumar, SM (NG P/L O&M), Extn 462 (Email: akash16011[at]gail[dot]co[dot]in)